Tactical fiber optic patch cable trunks and assemblies (TFOCA) are used in many applications that demand quick deployment, durability, resilience, and just as quick redeployment. These TFCOA cables are most often used in military applications, but there are many others. We examine the what, the where, and the why in this article.

What Is a Tactical Fiber Optic Trunk Cable?

A tactical fiber trunk is a fiber optic patch cable hardened to meet rigorous field requirements. The tactical label boils down to not only being sturdy but also re-deployable. They are rated for harsh environments, have a high degree of flexibility, are crush resistant, and often must be retrieved, moving from one assignment to the next.

Here are the critical requirements.

- Crush-resistant and highly durable fiber optic cables can be walked on, driven over, and used outdoors in all weather.

- Round compact cable design for easy deployment and retrieval. Pre-terminated with watertight connectors.

- High-strength, lightweight, rugged tight-buffered cables surrounded by a thick layer of aramid, specifically designed for field use.

- Helical-stranded flexible cores can endure demanding military pulls with outstanding mechanical protection for the optical fibers.

- Core-locked polyurethane jacket for high-strength, abrasion, and chemical resistance.

- Heavy-duty self-deployment reels that can be readily deployed and retrieved without damage to the fiber cables.

Where Is a Tactical Fiber Optic Patch Cable Used?

The term tactical most often describes military applications. And indeed, tactical fiber optic cable assemblies have a wide range of military uses. But they are by no means limited to military applications. Here’s a quick list.

- Broadcasting Applications. This includes remote video production, sporting event coverage, and news coverage. This also meets the requirements for outdoor concerts and political rallies with cables deployed for portable video walls, sound systems, and other communication requirements.

- Emergency Installations. When an existing fiber optic cable system is damaged due to weather, earthquake, or other disasters, temporary replacement tactical fiber optic cable assemblies can be quickly implemented.

- Mining and Exploration Applications. Deep mining and underground exploration require readily deployed communication cables in harsh, wet environments. They are also removed and deployed elsewhere as the mine expands or exploration takes a different turn.

- Communication and Security Systems. This applies to any critical communication lines that need to be installed on very short notice and re-deployed on similarly short notice. This could be due to emergencies or sudden requirements that weren’t easily foreseen.

- Military Tactical Deployments. This type of installation is at the heart of tactical fiber trunks. The environment is harsh and often extreme. As a result, the deployment is subject to rapid advances or tactical movements that happen on short notice.

The Why of Tactical Fiber Trunks—A Case Study

The many requirements and applications for tactical fiber optic patch cables are documented above. In addition, this type of fiber optic cable offers rapid deployment of rugged cables that can withstand the harsh environment and be reeled up quickly and deployed elsewhere.

To provide further insight, we’ve captured a case study of why the U.S. Navy chose our cables and how they were used.

During shooting and ammunition training at one of its bases, the U.S. Navy uses a high-tech method to analyze performance with the help of custom tactical fiber optic cable assemblies. This device monitors the biological and environmental effects on men and women in a high-heat desert environment.

In addition to the harsh outdoor application, the fiber optic patch cable assembly needed to meet extra durability and flexibility requirements to accommodate the required equipment mobility. This required mil-spec custom tactical fiber optic cable assembly on tactical cable reels, complete with IP67 and IP68 circular connectors.

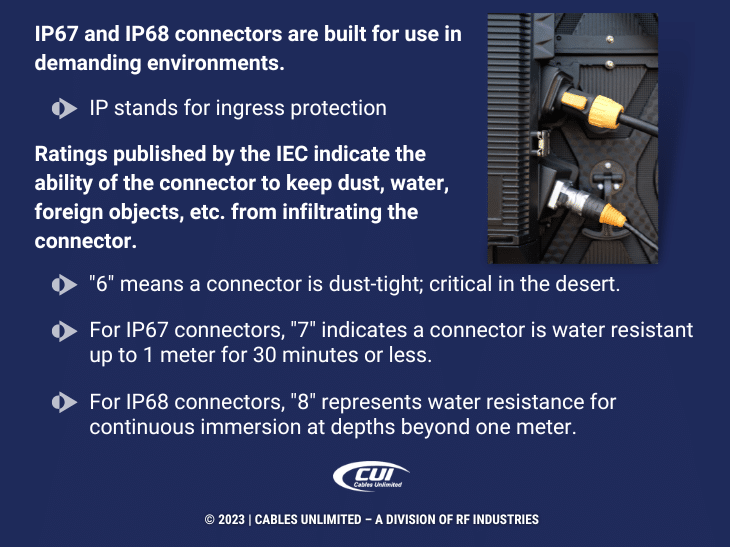

The IP67 and IP68 connectors are built for use in demanding environments. IP stands for ingress protection, and the ratings published by the International Electrotechnical Commission (IEC) indicate the ability of the connector to keep elements like dust, water, foreign objects, and more from infiltrating the connector.

Tactical Fiber Cables Made in the USA: Trusted By Military Forces for Reliability

In the IP connector ratings, six means that the connector is dust-tight, a characteristic critical to the assembly’s performance in a desert environment. For IP67 connectors, 7 indicates that the connector is water resistant up to 1 meter deep for 30 minutes or less. For IP68 connectors, 8 represents water resistance for continuous immersion at depths beyond one meter.

In the case of the military tactical fiber optic patch cable assemblies designed by Cables Unlimited, the rugged IP67 and IP68 connectors were chosen for their ability to prevent any dust or water they’d likely encountered in their outdoor application from damaging their operation.

The tactical fiber optic cable on tactical reels was designed with mobility and rapid cable deployment. Paired with the rugged construction of the fiber optic cable assembly, featuring high-quality waterproof IP 67 and IP68 connectors, the custom assembly was ideally suited to hard military use in the harsh desert environment.

We Can Meet Your Tactical Fiber Optic Patch Cable Needs

We are a Corning Gold House Partner and work with many other suppliers to source materials. We also have extensive in-house capabilities. Plus, we make it a point to work with USA-based suppliers, many of them located near our manufacturing facilities on both the east and west coasts.

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables Unlimited offers much more than state-of-the-art manufacturing—our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.