Navigating high-stress environments requires custom cable assemblies that can keep pace with extreme demands. With a market valued at $242.3 billion, cable assemblies create system reliability and performance across some of the most important sectors throughout the USA. At Cables Unlimited, our innovations set new standards for durability and efficiency. This article discusses how custom cable assemblies enhance operational capabilities in high-stress environments.

Performance Enhancements Provided by Custom Cable Assemblies

Whether managing operations in industrial environments, overseeing military equipment or ensuring reliability in aerospace technology, the enhancements that come with custom cable assemblies optimize your setup. They offer critical advantages to your projects. helping you exceed the rigorous demands of your specialized fields.

1. Increased Reliability Under Extreme Conditions

Custom cable assemblies are an important investment in the reliability of your operations. Designed to withstand the rigors of extreme environments, these assemblies use the best materials and construction techniques. They work to resist high temperatures, corrosive chemicals, and intense mechanical stress. This means your products provide continuous functionality in settings where standard cables would fail.

They have become indispensable for industries like oil and gas exploration, where the equipment needs to perform under high pressure and varying temperatures. With Cables Unlimited, we test each assembly to meet stringent standards, providing you with the assurance that your equipment has components that are resilient and reliable.

2. Optimal Electrical Performance

Custom cable assemblies improve your systems by precisely matching electrical properties like impedance, capacitance, and resistance to the specific needs of your applications. With this tailored approach, every watt of power is effectively used, minimizing energy loss, and boosting system efficiency. These represent critical factors in sectors such as aerospace and defense, where optimal signal integrity and performance can determine mission success. Additionally, these custom solutions reduce the risk of electrical noise and interference, common in high-density electronic environments. This allows for clearer signals and longer operational lifespans.

3. Superior Durability

With custom cable assemblies, durability is by design. Selecting materials that withstand harsh environments, such as high-grade polymers for insulation and rugged exteriors for sheathing, these cables stay functional through the physical stresses that would compromise lesser materials. For example, in robotic manufacturing, cables need to tolerate frequent bending and twisting without wear. Similarly, resistance to UV light and extreme weather conditions is vital in outdoor telecommunications. These customized cable solutions extend the lifespan of the cable assembly and reduce maintenance costs and downtime.

4. Compliance with Industry Standards

Custom cable assemblies comply with stringent standards such as ISO 13485 for medical devices, which govern the quality management systems of components used in healthcare. With our cable assemblies, every product meets the necessary safety and quality benchmarks. In aerospace, cables must conform to the AS9100 standard, which addresses the quality and reliability of components exposed to extreme environmental conditions. Automotive industries often require adherence to the IATF 16949, focusing on continuous improvement and defect prevention in automotive-related products.

This is important because it drives home how significant it is that our custom cable assemblies meet these specific regulations. With our products, you enhance the reliability and marketability of your own products, securing a competitive edge in industries where excellence is expected. This approach means you satisfy regulatory requirements while building trust with your clients by consistently delivering high-performance, compliant products.

5. Tailored for Specific Technologies

In a world where technology evolves at breakneck speed, custom cable assemblies provide the adaptability necessary to keep pace with innovation. These assemblies provide the flexibility to incorporate the latest advancements in material science and engineering. This feature provides enhanced conductive properties and increased environmental resistance, making them ideal for supporting cutting-edge technologies.

Whether it’s integrating fiber optics for superior data transmission or employing high-density connectors for miniaturized devices, custom cables can be precisely configured to match the technological requirements of any application. This equips your systems to meet future demands, effectively future-proofing your technological investments.

Strategic Implementation in Demanding Sectors

Custom cable assemblies allow for the seamless operation of equipment across various demanding sectors, enhancing cables for harsh environments. Each assembly meets the unique challenges of its application, enhancing system performance and reliability. Here’s how these specialized cables make a significant difference in military, industrial, and medical environments.

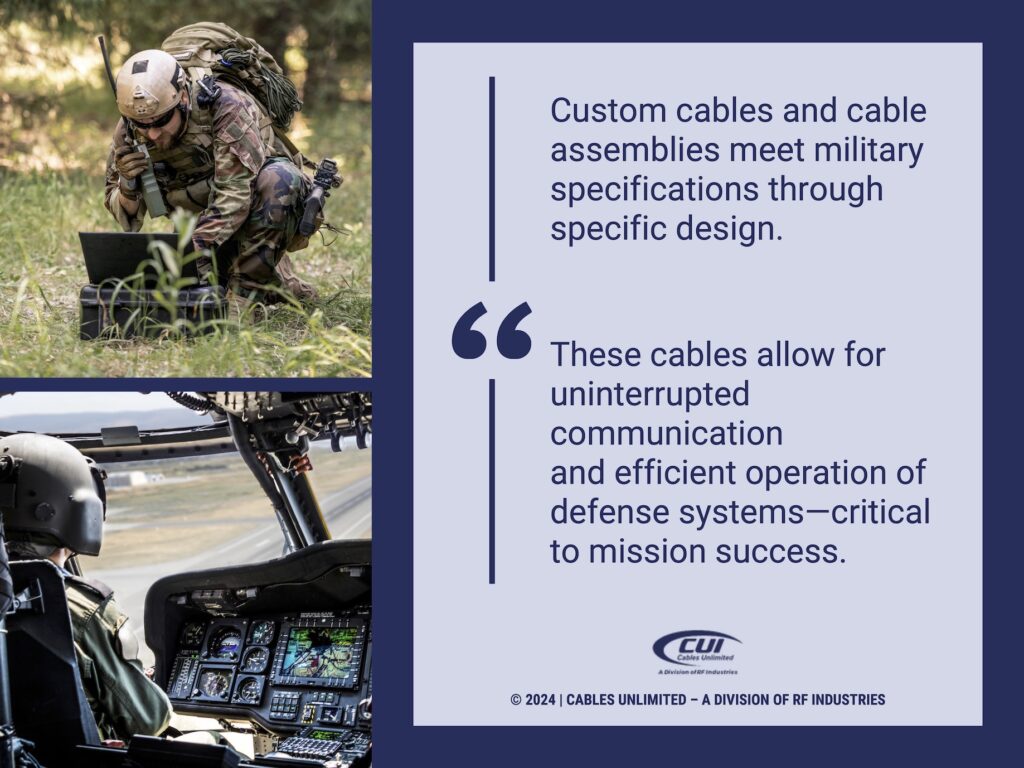

Military Cable Applications

In the military sector, the stakes are exceptionally high, and equipment must perform under extreme conditions without fail. Custom cable assemblies, combined with custom cables, meet military specifications through their specific design, offering enhanced durability and resistance to environmental stressors like moisture, dirt, and extreme temperatures. These cables allow for uninterrupted communication and efficient operation of defense systems, which your products must provide during critical missions.

Military Cable for Defense Projects in the USA: Challenges and Solutions

Industrial Automation

Automation systems are the backbone of modern manufacturing and require precision. Custom cable assemblies help you ensure that these systems operate smoothly without frequent interruptions. We build them to withstand the continuous stress of motion and exposure to industrial elements such as oils, chemicals, and vibrations, thereby optimizing the uptime and extending the lifespan of the automation equipment.

Medical Equipment

When it comes to medical technology, the accuracy and dependability of every component can be lifesaving. Custom cable assemblies used in medical devices are designed to meet strict health and safety standards, ensuring minimal electrical interference and high signal integrity. This is vital for the reliable performance of critical diagnostic and monitoring equipment that helps healthcare professionals provide the best care possible.

Ensuring Peak Performance With Custom Cable Assemblies

To maximize the potential of your high-stress systems, it is essential to partner with American cable manufacturers who understand your specific challenges. Custom cable assemblies offer a targeted solution that exceeds the standard requirements, providing enhanced performance and reliability where it counts.

Discover How Custom Cable Assemblies Can Elevate Your Operations

Custom cable assemblies play a key role in pushing the boundaries of what’s possible in high-stress environments. By providing tailored solutions that meet the exact specifications of your USA applications, they improve system performance, ensuring reliability, durability, and efficiency.

At Cables Unlimited, we work with you to design cable assemblies that help your systems perform at their best. Contact us today to see how we can help optimize your operations with cutting-edge cable solutions.