Fly-by-wire no longer refers to mechanical cables strung from the stick of a biplane to the flight control surfaces. Instead, it relates to moving electronic signals through aerospace cable assemblies and wire harnesses from every component of an aircraft, nose-to-tail, for monitoring performance and controlling their actions. Those aircraft wire harnesses and cable assemblies require the best aerospace cable manufacturer to ensure they perform flawlessly, no matter the stresses, strains, or environmental conditions.

This article examines what goes into manufacturing aerospace cable assemblies, including testing and how to find the best cable manufacturer in the USA.

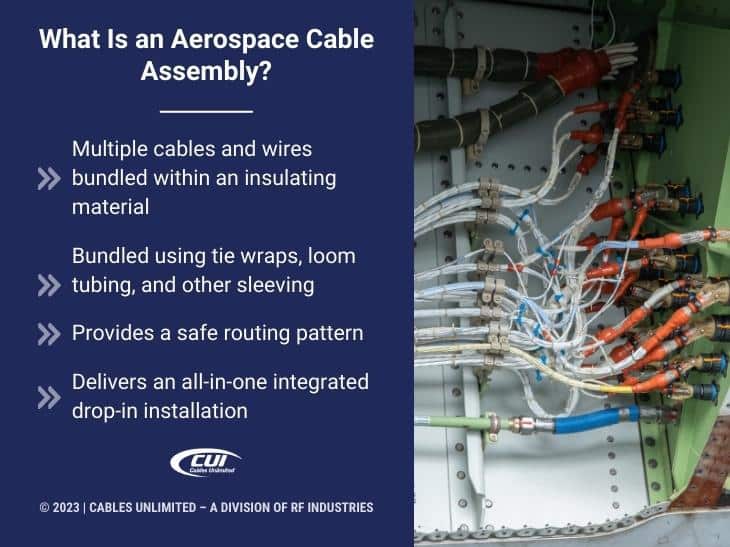

What Is an Aerospace Cable Assembly?

Aerospace cable assemblies and wire harnesses comprise multiple cables and wires bundled within an insulating material. It bundles the wires and cables using tie wraps, loom tubing, and other sleeving components. The cables and wires range from single conductors to fiber optics, coaxial cables to twisted pairs, and more.

Since the harness is bound together, it provides a safe routing pattern. It further simplifies the wiring interconnections by delivering an all-in-one integrated drop-in installation across multiple connection points. For more detail, see our article Wire Harnesses and Cable Assemblies — What’s the Difference?

Aerospace Cable Assembly Manufacturing Demands

The demands on aerospace cable assembly manufacturers are just as extreme as the operating environment for all aerospace applications. Here’s a quick breakdown of the extensive specifications and critical demands.

- High Quality – Meeting Detailed Specifications. A cable or connector failure can easily lead to loss in the air. With an aerospace application, that can either mean lost lives or, in the case of drones or satellites, lost valuable equipment. That requires an aerospace cable manufacturer to meet detailed specifications for high voltage, substantial vibration, high-impact contact force, extreme temperatures, radiation, and more.

- Strength and Reliability. Failure isn’t an option in aerospace applications. Testing can range from impact survival, vibration extremes, high pressure, abrasion, and wear to ensure strength and reliability requirements are met

- Extreme Environment Operation. Aerospace applications extend from flight in the Earth’s atmosphere anywhere around the globe to space applications in orbit around the Earth or even the Sun. Onboard cables need to handle it all and keep working flawlessly. The design of cables in these environments must take in all the relevant factors, from temperature extremes to radiation exposure.

- Complex Applications. The applications in aerospace industries range from aircraft and surveillance drones to satellites and solar probes. It requires great expertise and experience to manufacture the custom cables to fit these applications and meet their rigorous quality specifications.

Aerospace Cable Manufacturer Testing Requirements

It’s one thing to work through all those aerospace specifications in designing and constructing custom cables. It’s yet another to implement all the rigorous testing that ensures the cables meet those requirements. It’s not always the case that once the cable is built to the specifications, it will perform to those exact specs.

That’s why Cables Unlimited is certified under the AS9100 Standard from the Aviation, Space, and Defense (ASD) industry. This standard requires “creating and maintaining a comprehensive quality system for providing safe and reliable products to the ASD industry.”

The AS9100 is not a product or personal standard; it asks the company to control processes so the end product meets customer requirements and satisfaction. Benefits for obtaining the certification are extensive, the least of which is the endorsement by all major aerospace regulators, including the Federal Aviation Administration (FAA), the US Department of Defense (DoD), and the National Aeronautics and Space Administration (NASA).

Find out more in our article Importance of Quality Control in Military and Aerospace Cables.

How to Choose a Cable Manufacturer for Aerospace Cable Assemblies

Choosing the best cable manufacturer for your business is critical for your success and the success of your projects. As you know, it’s not easy to manufacture cable assemblies for aerospace applications. It requires years of experience and deep expertise in delivering top-notch customized aerospace cable assemblies and fiber optic cables and always doing so on time.

In our article 10 Tips for Choosing the Right Cable Harness Manufacturer we’ve outlined the key things to look for when selecting your supplier. They include expertise and experience in your industry, producing cables that match your needs, delivery speed, component sourcing capabilities, and lower product costs. You should also expect extensive design, production, and testing resources, including skilled people and the necessary equipment.

The Benefits of USA Cable Manufacturing

There is a wide range of critical issues facing any aerospace cable manufacturer. They include raw materials access and delivery and finding and training employees. There are many advantages of working with a USA supplier. Here are a few.

- Accessible Communication and Collaboration. Speaking the same language and sharing common cultural factors and similar time zones can significantly improve communication. Not only that, but you can quickly stop by the supplier’s facility to check progress and readily solve any problems.

- Quality Assurance. That improved communication ties directly to the overall quality assurance process. Not only are standards often higher in the USA, but the ability to respond to any issues rapidly before large numbers of manufactured components compound them makes domestic manufacturing very cost-effective.

- Manufacturing Flexibility. Overseas manufacturers typically require large production runs to offset setup, sourcing, and shipping costs. On the other hand, many USA manufacturers can readily accommodate smaller production runs and more frequent runs to match your just-in-time inventory needs.

- Faster Fulfillment Times. With a USA cable manufacturer, you can often find quicker turn-around times from order to delivery.

- Reduced Shipping Costs. You can save on transportation without customs fees and long-range ocean shipping costs.

- Higher Labor Standards. The USA has rigorous standards to protect employees and meet those higher work standards.

- Protection of Intellectual Property. The USA’s rigorous standards extend to the protection of intellectual property. Given that, there’s far less likelihood that your latest, greatest product will end up on the shelves of some other manufacturer.

Read more in our blog: USA Aerospace Cable Excellence: Leading the Industry in Quality Assurance

We Can Meet Your Aerospace Cable Manufacturing Needs

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.