When looking for custom cable assembly manufacturing options, it’s wise to search diligently for the right manufacturer for your requirements. We’ve addressed this topic at length in our article 10 Tips for Choosing the Right Cable Harness and Assembly Manufacturer. What happens once that critical task is accomplished? Find out in this article.

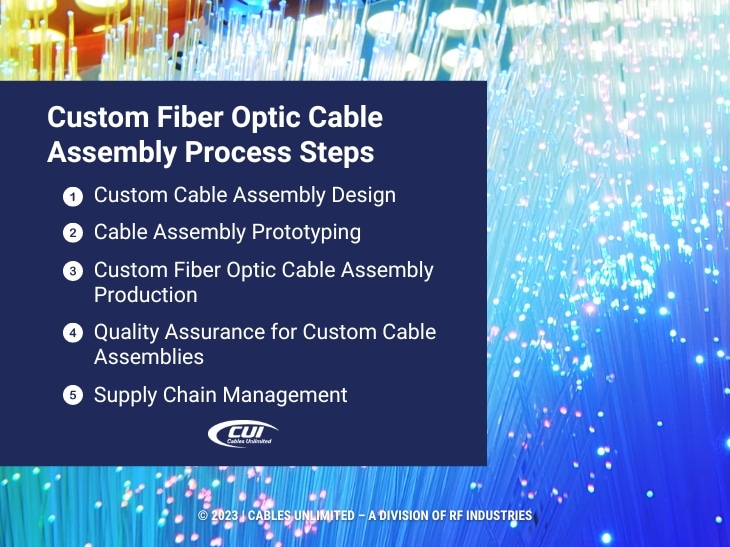

Custom Fiber Optic Cable Assembly Process Steps

It all starts with the exact specifications for your custom fiber optic cable assembly. You’ll then work closely with your chosen manufacturer using a thorough, painstaking production process to ensure you receive a top-quality cable assembly that precisely matches your requirements. Here are the manufacturing process steps that bring this all about.

- Custom Cable Assembly Design. The design stage is the first step in any custom cable assembly development. It typically requires defining product requirements and the resulting performance criteria. Once the designer builds the drawings and verifies that they meet the requirements, they will make the detailed specifications list and bill of materials that drive the next steps.

- Cable Assembly Prototyping. Once the design is completed, the next stage is taking all the required parts and assembling a prototype. That process is designed to reveal parts sourcing problems and to test various iterations of the custom fiber optic cable assembly design. This will lead to finding the best assembly options and verifying that all requirements and performance criteria have been met.

- Custom Fiber Optic Cable Assembly Production. It begins with the basic fiber optic cable or multiple cables as specified in the design stage. That’s followed by fiber optic cable cutting, polishing, and connector installation. That’s then followed by encasing the assembly within a single tube of heavy duty material to provide the needed protection.

- Quality Assurance for Custom Cable Assemblies. This is all about extensive product testing that covers the broad areas of physical analysis, environmental analysis, signal integrity analysis, and insertion loss analysis. The physical analysis includes pull testing of terminations. The environmental analysis covers extreme temperatures, dust, and moisture. Signal integrity includes ensuring the signal is where it needs to be at the termination. That is also extended to the insertion loss analysis.

- Supply Chain Management. This starts at the beginning of the process during design and prototyping, ensuring that the needed components will be available for manufacturing and the product’s lifetime. It begins with forecasting and, at the tail end of the cable assembly’s lifetime, finding suitable substitute components. Sourcing components is also a critical element of the overall cost of any custom fiber optic cable assembly.

What to Look for in a Custom Fiber Optic Cable Assembly Manufacturer

We’ve written extensively about the importance of finding the right custom cable assembly manufacturer. It’s critical to the operation of your products and your business. It’s no good going through the design, prototyping, production, and testing process to find that your product doesn’t work as required. That’s a disaster.

We recommend a rigorous review of any prospective custom fiber optic cable manufacturer that considers these essential items.

- Broad Custom Cable Assembly Experience. Experience should be measured in decades; during that time, the manufacturer should improve and advance their skills. So it’s not one year of experience repeated but involves continuous improvement.

- Industry-Specific Experience and Expertise. Prospective manufacturers should have extensive experience in your industry. Do not finance their education with your projects.

- Cable Types that Match Your Needs. The right custom cable assembly manufacturer must also have experience with your specific cable type. But, again, your projects do not need to be a learning experience for them and their business.

- Extensive Design, Production, and Testing Resources. You’re seeking a custom cable assembly manufacturer because you don’t have the resources or expertise to do it yourself. Make sure the manufacturer you choose has those resources and expertise in abundance.

- Component Sourcing Capabilities. Finding and buying the necessary components is crucial to manufacturing custom cable assemblies. Therefore, the chosen manufacturer should have extensive sourcing capabilities.

- Certifications and Regulations. Custom fiber optic cable assemblies require expertise backed by industry certification, recognition, and regulation compliance.

- Top Level Customer Service. The best manufacturers engage you from your first moment of contact and through every step of every project. You can tell from the first call that they have your interests at heart.

We Can Meet Your Custom Cable Assembly Manufacturing Needs

Look no further. We match all the characteristics of the right custom cable assembly manufacturer. We can and will meet all your requirements.

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing—our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.