Fiber optic cables offer several advantages over copper. We covered them in detail in our Fiber Optics in the Future article. Those advantages include low cost, lightweight, low signal loss, long life span, immune to EMI and RFI interference, and security from data leaks. They are also physically strong and well-suited to outdoor installations. This article addresses the types of outdoor cables and their pros and cons, which can help you choose the right outdoor fiber cable.

Fiber Cable Construction

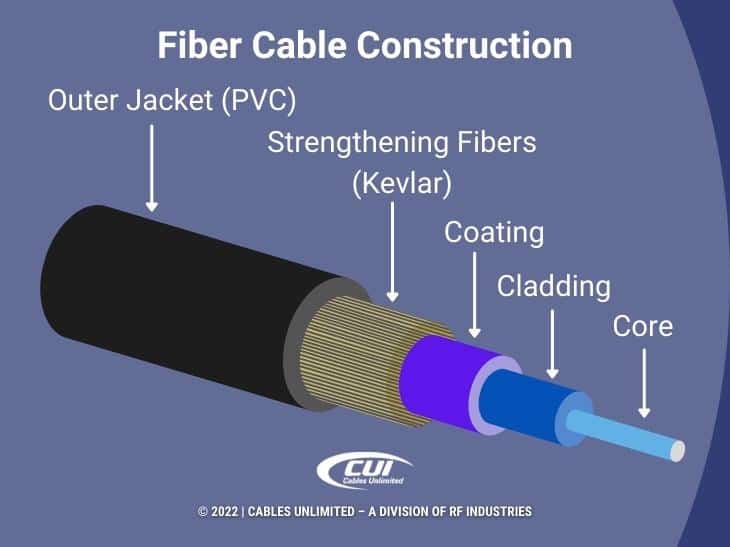

The center of a fiber optic cable is a thin glass tube called the core, which moves the light pulses. It may be a single-mode or multimode core. The next layer is called cladding, a thin layer of glass that reflects the light back into the core. The coating around that is a buffer to absorb shocks and reinforce the core. Next up are the strengthening fibers often made of Kevlar. They can also be gel-filled sleeves. These protect the fiber core from excessive pulling or crushing forces during installation.

The outer jacket is the final layer, where outdoor protection comes into play. The jacket can be made from a variety of materials. Fire-resistant polyvinylchloride (PVC) is used indoors. Polyethylene (PE) is preferred for outdoor use as it is resistant to moisture, abrasion, and ultraviolet (UV). It also maintains its flexibility over a considerable range of temperatures.

Types of Outdoor Fiber Cables

There are several major types of outdoor fiber cables, each with pros and cons, which can help you zero in on the best fiber cable for any installation.

- Standard Indoor/Outdoor Cables. This type of cable doesn’t have the strong protective jacket of other outdoor cables, but they are well suited for installation between the indoors and outdoors. They are low-cost but do not offer protection from rodents. They also must be installed outdoors in conduits or ducts since they should not be exposed to water.

- Ruggedized Indoor/Outdoor Cables. The ruggedized cables have a thicker outer jacket, providing abrasion and handling protection and protection from rodents. They are low to moderate cost, allow direct transition between indoors and outdoors, and offer easy handling. Outdoor installation should be in ducts or conduits to guard against abrasion and water.

- Armored Direct Burial Cables. This cable type uses a gel-filled construction with an armor shield under the outer jacket. It is rated for direct burial and will withstand rodents, freezing, and even light crush forces. It doesn’t need a conduit or duct. And is extremely durable. The disadvantages are the larger diameter cable with difficulty handling due to the heavy weight and limited bend rating.

- Aerial Outdoor Cables. They are used for utility pole installation. As such, they have a high-tensile strength steel messenger bonded to the fiber cable to provide the strength needed to hold it up between the poles. Of course, as durability goes up, so does the cost. This type of cable is ideal for small cell installations.

- Submarine/Underwater Cables. At the top of this type of cable are those used in transoceanic installations with extremely rigorous requirements. But there are also installations that install cables across rivers and lakes. These cables are not only rugged but provide an extremely clear fiber, allowing longer distances between repeaters.

Choosing the Right Outdoor Fiber Cable

From indoor/outdoor to direct burial to underwater, these cables are made specifically for each application. Given that, choosing the right cable is more of a matter of clearly defining your specific application and then selecting the optimum cable. That, of course, considers advantages and disadvantages in addition to cable and installation costs.

We Can Help with Your Fiber Cable Selection

We can help you make those critical choices of cables. We have extensive experience manufacturing a wide range of fiber cables. Plus, we’re a Corning Gold House Partner with all the support and benefits that it brings.

Our name is Cables Unlimited for a reason. Whatever outdoor-rated cable assemblies you need, we can provide them.

If your requirements are already specified and ready for a quote in your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. You can also send us an email or complete our contact form, and we’ll get right back to you.