Radiation in the form of gamma rays, X-rays, neutrons, protons, and others can severely increase the attenuation of fiber optic cables. This happens in aerospace and military applications, and nuclear reactors. It’s called Radiation Induced Attenuation (RIA). In some cases, removing the radiation source can reverse the attenuation, but this may not be possible in aerospace, military, and nuclear reactor cables. That’s where radiation-hardened fiber is required.

This article defines radiation-hardened fiber and examines the causes of radiation-induced fiber optic cable losses. It further explores manufacturing requirements, advantages, and applications for radiation-hardened fiber.

What Is Radiation-Hardened Fiber?

A radiation-hardened fiber is made to withstand radiation pulses and recover its transmission characteristics within a specified period. Careful consideration is given to the exact molecular construction of the cable’s core and cladding materials to provide initial radiation resistance and limit degradation over time. These fiber optic cables are also referred to as radiation resistant or radiation tolerant. They can prove extremely valuable in fiber optic cable aerospace and military cable.

Causes of Radiation-Induced Fiber Optic Cable Losses

The primary cause of radiation-induced fiber optic cable losses is attenuation, where the radiation increases propagation loss due to the absorption and scattering of light. There can also be radiation-induced luminescence or phosphorescence that disrupts sensor results. Similarly, there can be radiation-induced changes in the refractive index, causing the same issues.

Manufacturing Requirements for Radiation-Hardened Fiber Cables

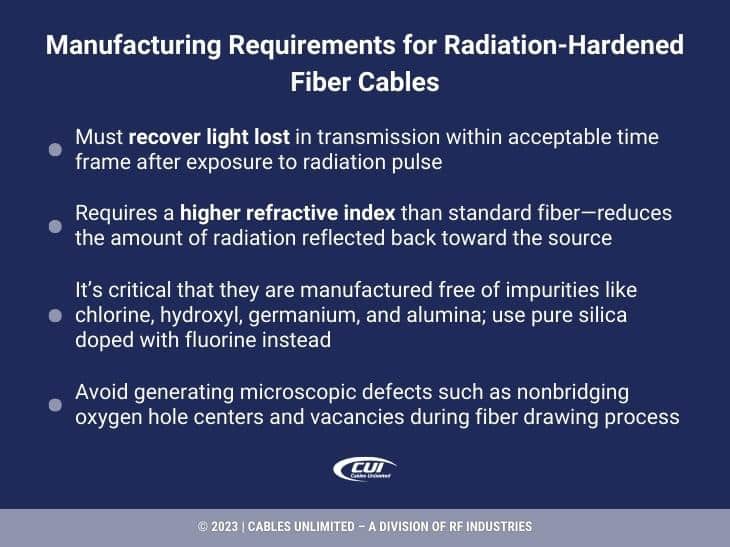

The core and cladding materials of radiation-hardened fiber are designed to recover the light lost in transmission over a given distance. This needs to happen within an acceptable time frame after exposure to a radiation pulse. This is important for maintaining the desired level of optical performance in aerospace fiber optic cable.

Radiation-hardened fiber also requires a higher refractive index than standard fiber. This reduces the amount of radiation reflected back toward the source. These cables are often made with reinforced outer jackets and connectors to further protect against the effects of radiation.

Manufacturing fibers free of impurities such as chlorine and hydroxyl is a critical aspect. Further, doping of the fibers needs to avoid germanium and alumina, instead using pure silica doped with fluorine. Hydrogen, deuterium, or oxygen loading of the fiber has been found useful. Plus, as noted above, coatings and shielding can prove helpful not only for radiation hardening but also for the strength of the cable.

Finally, the fiber drawing process must avoid generating microscopic defects such as nonbridging oxygen hole centers and vacancies. These defects can be transformed by radiation into absorption bands.

What Are the Advantages?

In addition to providing superior protection against radiation, radiation-hardened fiber offers several other advantages over standard fiber. This type of cable is more reliable and requires less maintenance, as it is less likely to suffer from the effects of aging. It can also be used in harsher environments, as its design is resistant to extreme temperatures, humidity, and other environmental factors.

All this comes in addition to the inherent advantages of fiber optics in military and aerospace cables: lower cost, lighter weight, thinner diameter, higher speed, wider bandwidth, lower signal loss, longer life span, and greater security.

Read more in our blog: USA Military Cable Tech: Adapting to Extreme Environments

Radiation-Hardened Fiber Applications

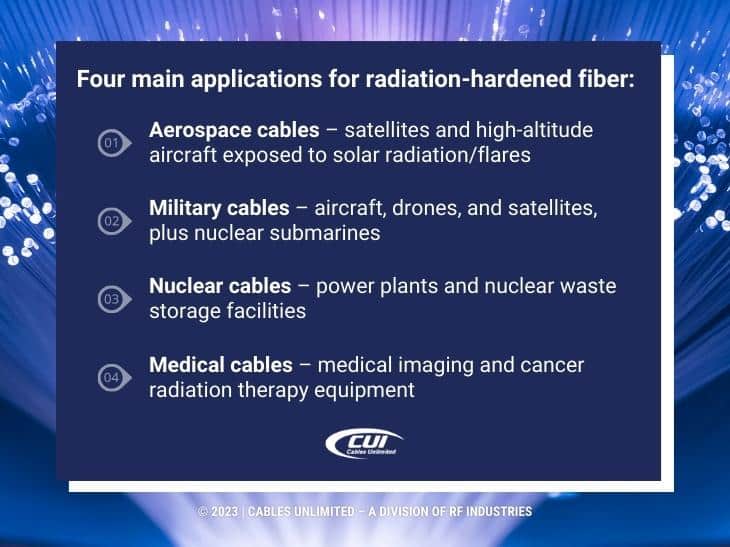

There are four main applications for radiation-hardened fiber.

- Aerospace Cables. Satellites are exposed to solar radiation, including intense solar flares. This also applies to aircraft at high altitudes. These cables need to be resistant to the initial radiation pulse and provide a fast recovery once the pulse has subsided.

- Military Cables. This includes aircraft, drones, and satellites, plus nuclear submarines. Military applications include aircraft flying at high altitudes and weapons systems that may be exposed to nuclear explosions.

- Nuclear Cables. Power plants and nuclear waste storage facilities use fiber cables to monitor processes and the status of highly radioactive substances. Radiation-induced fiber optic anomalies can seriously disrupt operations and also degrade cable performance over time.

- Medical Cables. Medical imaging and cancer radiation therapy generate a high amount of X-rays and proton radiation. These fiber optic cables need to take this into account to avoid any disruption, erroneous measures, or errors in treatments.

We Can Meet Your Military and Aerospace Cable Needs

Whether you need radiation-hardened fiber for military and aerospace cables, nuclear installations, or medical applications, we’ve got you covered.

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables Unlimited offers much more than state-of-the-art manufacturing—our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround-time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.