High-temperature cables are used to meet the demands of extreme environments. That includes everything from industrial applications to satellites and the rockets used to get them into orbit. This article addresses all aspects of high-temperature electrical cable: definition, degradation causes, materials for conductors and insulators, and the broad range of applications.

What Is a High-Temperature Cable?

A high-temperature cable is any wire or cable with an operating temperature of 150° C or higher. A high-temperature rating should not be confused with heat-resistant wire or cables. Heat-resistant wires typically operate between 90° and 105° C, a common rating for wires and cables.

High-temperature cables and wires are used in locations and equipment exposed to extreme heat. This ensures their safe operation and long-term durability in harsh environments. That level of operation requires the best materials and techniques from cable manufacturers.

Causes and Effects of High-Temperature Cable Degradation

High temperatures cause thermal expansion, followed by contraction as temps decline. Over time, that contraction and expansion cause cracks and breaks in the conductor and the insulation. That also causes thermal aging as the temperature variations break down the polymers in the installation. In addition, insulation cracks can lead to moisture entering the cable, resulting in corrosion.

Cracks, breaks, aging, and corrosion deteriorate electrical performance, including increased resistance and signal loss. It can also lead to a higher risk of fire hazards. Plus, there’s the repair and downtime cost when failures occur.

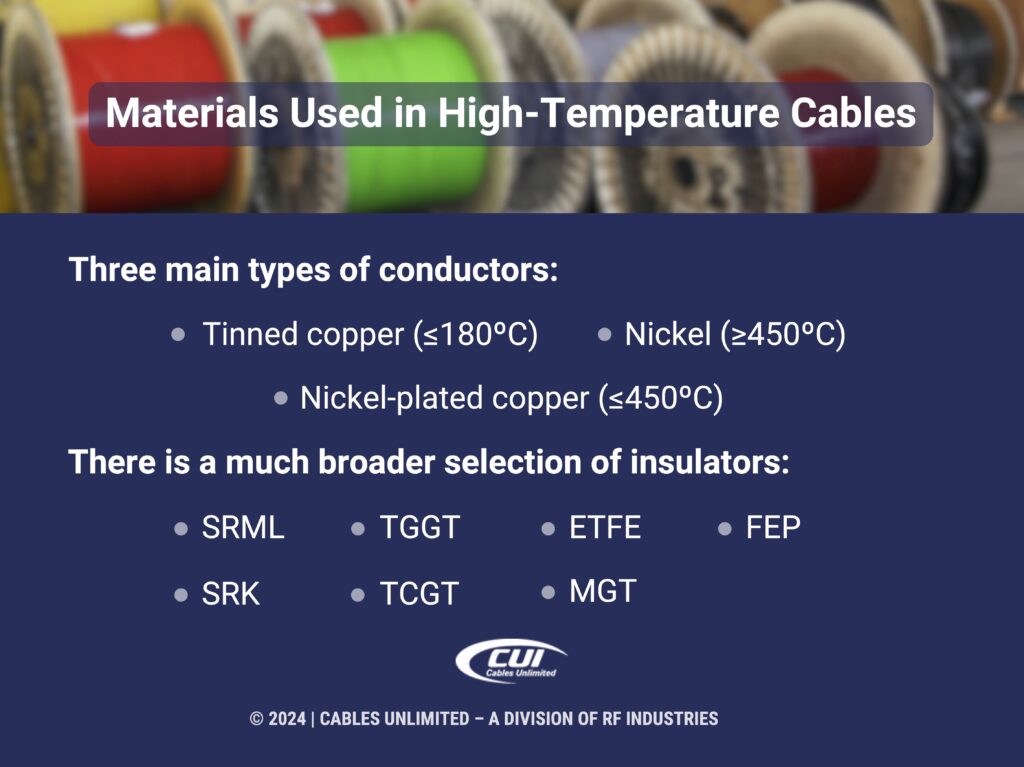

Materials Used in High-Temperature Cables

Specific conductors, insulators, and jackets are used to increase the temperature rating to avoid the effects of high-temperature cable degradation.

The three main types of conductors are tinned copper, with a rating of up to 180° C; nickel-plated copper, up to 450° C; and nickel, which can reach above 450° C.

There is a much broader selection of insulators. Here’s a short list of options to consider.

- SRML. Silicone rubber motor lead is used in auto motors and electrical applications such as sun lamps with temperatures not exceeding 150° C. SF2 is similar but can withstand 200° C. SFF2 is more flexible with a higher strand count but only up to 150° C.

- SRK. Silicone rubber K-fiber jacket is rated at 200° C and is used in melting systems for glass plants and steel mills.

- TGGT. This is Teflon glass, glass Teflon. It uses a polytetrafluoroethylene (PTFE) tape insulation covered by a high-temp sealant-infused fiberglass jacket. It is used in heaters, ovens, and kilns with a rating of up to 250° C.

- TCGT. This variation of TGGT uses a ceramic tape jacket instead of a TGGT fiberglass jacket.

- ETFE. Ethylene tetrafluoroethylene copolymer has similar properties to PTFE and can withstand temperatures up to 150° C with extreme temperatures up to 300° C for seven hours.

- MGT. This is mica glass tape. The MG insulation has multiple layers of mica and glass covered by a fiberglass jacket. There is also a version that is protected by a PTFE moisture barrier. It’s used in cement kilns, electric heaters, and commercial ovens. It’s rated up to 450° C.

- FEP. Fluorinated ethylene propylene is used for temperatures up to 200° C. It protects from moisture and abrasion. It’s used in medical and chemical applications.

In general, jacket materials are selected from the same list above. In some cases, however, a second jacket can be made from fiberglass or aramid fibers for additional heat resistance.

Cable manufacturers use all these materials to produce custom cable assemblies, custom data cables, and a complete range of high-temperature electrical cables, including high-temperature flexible cables for harsh environments. Ideally, you’ll be working with a USA-based cable manufacturer. For background on the benefits of local manufacturing, see How to Choose Your Fiber Optic Supplier and Manufacturer in the USA.

High-Temperature Cable Applications

There is a wide range of applications for high-temperature cables. Here’s a starting list.

- Automation and Robotics. Foundries and manufacturing facilities use high-temperature cables to power and control robots and other applications. These cables need to stand up in the high temperatures of molten metal casting operations.

- Industrial Machinery. It doesn’t have to be automated. Any machinery on the shop floor can be subjected to high temperatures and other harsh environmental conditions.

- Electrical Power. Turbines in power plants and wind farms require high-temperature cables to withstand extremes in temperatures. Transformers must also endure high temperatures.

- Household Appliances. A wide range of appliances throughout the home require high-temperature cables and wires. That includes ovens, dryers, lighting fixtures, microwaves, toasters, and more.

- Medical Equipment. High-temperature cables, from X-ray machines to CAT scans to thermal surgical instruments, are required with the utmost reliability.

- Automotive. Engine management, including exhaust temperature sensors, requires high-temperature cables. In addition, electric vehicle charging systems are subject to high temperatures.

- Marine. Shipboard electrical systems, from engines to electrical power to navigation systems, require high-temperature cables. Offshore gas and oil platforms and underwater vehicles have similar demands.

- Telecommunications. Data centers and cellular towers all need high-performing cables in extreme temperatures.

- Aerospace. From aircraft engines and avionics to missiles and satellites, high-reliability cables are essential for safe operation. That includes withstanding high temperatures.

We Can Meet Your USA-Manufactured High-Temperature Cable Needs

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.