There are several different types of fiber optic cables, specified by rigorous standards, each with its advantages from speed to bandwidth to distance. This article explores these differences and examines their use in fiber optic cable assemblies, wire harnesses, and hybrid cables.

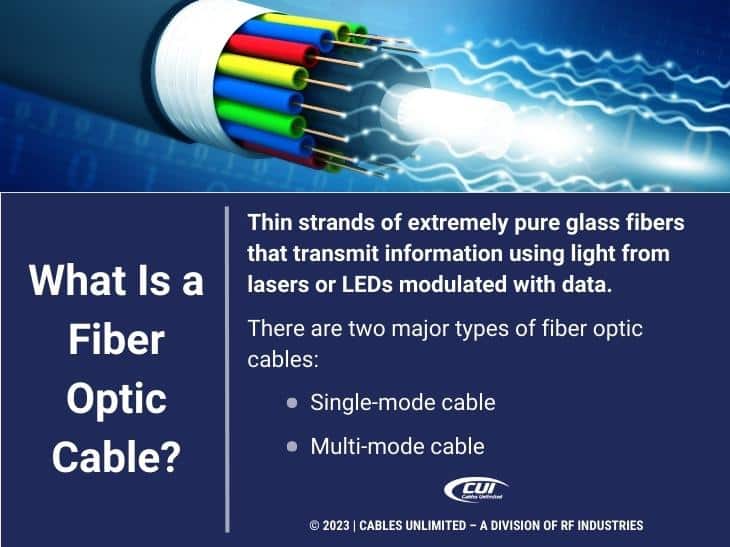

What Is a Fiber Optic Cable?

At its most basic form, fiber optic cables are thin strands of extremely pure glass fibers. Each fiber also has an internal cladding that bounces light inward to prevent signal loss. They transmit information using light from lasers or LEDs modulated with data.

There are two major types of fiber optic cables, single-mode and multimode. Single-mode cable is used for long-distance network connections. It typically has a cable diameter of 9 microns, and just one wavelength of light can be transmitted. This minimizes attenuation due to decreased internal reflections.

Multimode cable has a greater diameter running from 50 microns to 62.5 microns. It can handle several wavelengths of light and multiple signals at high speeds. It’s used over shorter distances within a data center or local area network.

Fiber Optic Speed and Distance Comparison

The charts below quickly compare single-mode and multimode fiber optic cables.

| Single-Mode Fiber | Typical Data Rate | Distance |

| OS1 | 1 to 10 GB at 1550 nm | Up to 10 kilometers |

| OS2 | 1 to 10 GB at 1550 nm | Up to 200 kilometers |

| Multimode Fiber | Typical Data Rate | Distance |

| OM1 | 100 MB at 850 nm | Up to 33 meters |

| OM2 | 1 GB at 850 nm | Up to 82 meters |

| OM3 | 10 GB at 850 nm | Up to 300 meters |

| OM4 | 40 GB at 850 nm | Up to 550 meters |

| OM5 | 100 GB at 850 to 950 nm | Up to 500 meters |

OS2 fiber is the best option for long distances, with transmission rates over 10 GB and distances of up to 200 km. OS1 can only reach 10 km distances. Both handle only single data channels.

In contrast, OM5 fiber optic cable can handle at least four WDM (wave division multiplexing) channels across the range of 850 to 950 nm. OM1 to OM4 fibers can handle only one channel.

Custom Fiber Optic Cable Assemblies

As you can see from the above information, fiber optic cables can be used for long-distance transmission for cable television or internet systems. They can also be used in data networks and various applications across several industries. For more information, see our article 10 Uses of Fiber Optic Cables.

Most applications, from military to aerospace to computer networking, use custom fiber optic cable assemblies. A cable assembly is two or more conductors within a single insulating jacket. These assemblies provide the advantages of pre-testing, manufacturing in quantity, and dropping into place in the field. Not only that, but compared to field installation, pre-terminated fiber optic cables can save money.

Dig deeper with our article Custom Fiber Optic Cable Assemblies: Cost and Time Advantages.

Custom Fiber Optic Wire Harnesses

A wire harness is a bundle of separate wires and cables that, while held together, can still be broken out and routed independently. The wire harness bundles the wires and cables using tie wraps, loom tubing, and other sleeving components. The cables and wires range from single conductors to fiber optics, coaxial cables to twisted pairs, and more.

Since the harness is bound together, it provides a safe routing pattern. In addition, it further simplifies the wiring interconnections by delivering an all-in-one integrated drop-in installation across multiple connection points.

For more information, see our article, Cable & Wire Harnesses: Everything You Need to Know.

Custom Hybrid Fiber Optic Cables

A hybrid cable is a single cable with multiple types of fibers, conductors, and connectors. They can contain various AWG-size wires, coaxial and ethernet cables, fiber optics, etc. They are also built with the exact jackets needed, including PVC, Plenum, and LSZH, which are heat, moisture, and UV resistant. Not only that, but they are also built with the exact type of shielding needed for each specific installation. Add the required strain reliefs, desired color, logos, and text, and you have a hybrid cable.

For more, see our article Hybrid Cable Customization: Off-the-Shelf Cables Can’t Compete.

Custom Fiber Optic Cable Assembly, Wire Harnesses, and Hybrid Cable Manufacturing and Testing Standards

One of the significant advantages of cable assemblies, wire harnesses, and hybrid cables is that they are manufactured and tested before installation. This avoids costly troubleshooting after the equipment is assembled.

The starting point for testing and manufacturing is the IPC/WHMA-A-620 standard. It provides every cable manufacturer guidance on what is acceptable and what is considered defective. This standard goes into every detail, from insulation and crimps to connector installation.

The Cables Unlimited checklist includes: labeling, continuity, wire gauge measures, crimp analysis, insulation, and even pull tests for broken wires and short circuits.

Here’s a quick list of the critical manufacturing requirements.

- Quality. A cable or connector failure can easily lead to failure in the field. That requires meeting specifications for high voltage, vibration, contact force, extreme temperatures, and more.

- Strength and Reliability. Strength and reliability testing can range from impact survival, vibration extremes, high pressure, abrasion, and wear.

- All-Environment Operation. From applications in the arctic and the desert, under the ocean, to space applications, custom cable assemblies need to handle it all and keep working.

We Can Help With Your Custom Fiber Optic Cable Assembly, Wire Harnesses, and Hybrid Cable Specification and Selection

We’ve got you covered for fiber optic cable assemblies. The list includes DAS cables, trunk cables, patch cables, MTP®/MPO cables, macro cables, small cell cables, OptiFlex™ Hybrid Composite Cables, IP outdoor rated cable assemblies, and custom fiber optic cables.

Plus, we are a Corning Gold House Partner and work with many others to source the right materials for your fiber optic cable assemblies, wire harnesses, and hybrid cables. We also have extensive in-house capabilities.

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.