Custom cables are essential components across almost any industry in the USA, providing tailored solutions to meet specific requirements. These industries span from wireless communications to aerospace, each relying on custom cable assemblies from Cables Unlimited for efficient and reliable operations. This article discusses the role custom cables play in these industries.

Wireless Industry Custom Cable Assemblies

The wireless industry in the USA depends heavily on data cable to make sure they always have seamless communication. With over 330 million mobile devices in use, maintaining strong signal integrity is extremely important for your network. Custom cable assemblies designed for wireless applications reduce electromagnetic interference and maintain clear signal transmission for your customers. These cables need to withstand environmental challenges and continuous use so you can provide reliability and performance. Additionally, they need to handle high data rates and provide consistent connectivity in urban and rural areas. Investing in high-quality custom cables allows you to improve the performance and reliability of wireless communication networks, supporting the growing demand for mobile connectivity.

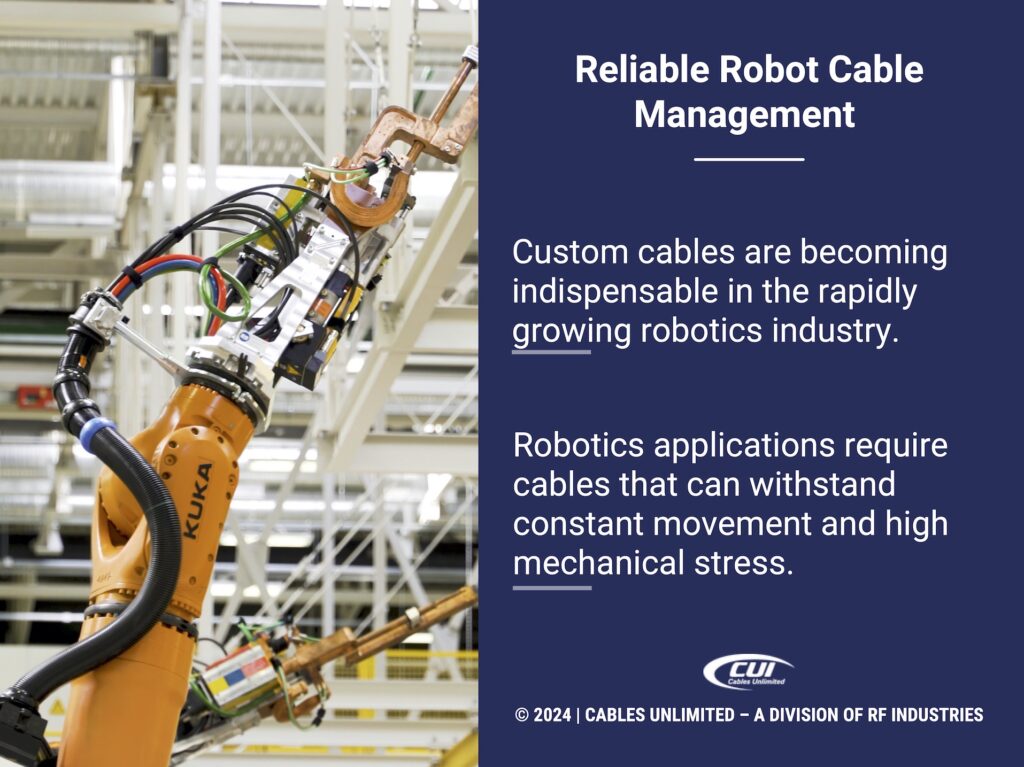

Reliable Robot Cable Management

In the rapidly growing robotics industry, custom cables are becoming indispensable. The robotics market, valued at $34.06 billion in 2022, is projected to reach $134.64 billion by 2031. When building your robotics applications, you need cables that can withstand the constant movement and high mechanical stress of your products. Custom cable assemblies offer flexibility and durability for robotic arms and automation cable management.

- Flexibility and Durability: Custom cables for robotics need exceptional flexibility to handle continuous motion. These cables maintain performance under high mechanical stress, so they don’t break or wear out quickly. At Cables Unlimited, we use high-quality materials that extend the lifespan of your robotic systems.

- Resistance to Harsh Environments: Robotics cables also need to resist oil, chemicals, and extreme temperatures. These cables are built to hold up under these conditions without degrading. This resistance keeps your robotic systems operational in the most demanding environments.

- Enhanced Performance: Additionally, custom cable assemblies strengthen the performance of robotic systems. They provide reliable power and data transmission, allowing for precise operations.

Robotic Cable Assembly Manufacturing: Insight Into Applications and Requirements

Enterprise and Data Center Industry

Data centers house millions of servers that rely on custom cables for efficient data transmission and network connectivity. With the increasing demand for data processing, custom cable assemblies work to minimize latency and maximize performance. Fiber optic cables, in particular, are important for high-speed data transmission over long distances. You need to make sure that you have proper cable management and adhere to industry standards so that you maintain uptime and scalability in data centers. These custom solutions also allow for future growth, accommodating expanding data requirements.

The industrial sector requires custom cables to withstand harsh conditions, including extreme temperatures, chemicals, and mechanical stress. These cables are used in machinery, automation systems, and manufacturing processes. Custom cable assemblies designed for industrial applications provide durability and reliability essential for maintaining productivity and safety. Heavy-duty jackets and robust insulation protect the cables from environmental hazards, ensuring long-term performance.

For example, cables in automated production lines must endure constant movement and exposure to corrosive substances without degrading. By using cables tailored to your specific industrial needs, you can enhance the efficiency and safety of your operations.

Satellite Industry

Satellites operating in space face extreme conditions, from temperature fluctuations to radiation. Custom cables for satellite systems must be lightweight but still durable. They also need to withstand these harsh conditions without compromising performance. Materials like FEP and PUR are commonly used for their resistance to temperature and radiation. These custom cable assemblies ensure reliable signal transmission between satellites and ground stations, supporting communication and data transfer. With the growing number of satellites launched annually, the demand for high-quality custom cables continues to rise. Specialized cables give you longevity and success for all of your satellite missions.

Custom Cables for the Military & Aerospace Industry

Custom cables in the military and aerospace industry are required to meet stringent specifications so your end user gets performance and reliability in critical applications. Data cables used in aircraft and defense systems must withstand high G-forces, extreme temperatures, and exposure to hydraulic fluids and de-icing agents. Custom cable manufacturers in the USA are required to test all cables for tensile strength, flexural endurance, and resistance to fuel and oil. Custom military and aerospace cables from Cables Unlimited provide consistent performance in the most challenging environments, supporting mission-critical operations.

Why Custom Industrial Cables Are Essential for U.S. Businesses

Transatlantic Telecommunications Cable for Worldwide Communication

The telecommunication industry is another sector that relies on custom cables to maintain global connectivity. With approximately 900,000 miles of submarine communication cables, custom cable assemblies are a big part of transmitting data across continents. These cables handle high data volumes and ensure signal integrity. By using advanced materials and shielding techniques, our cables prevent signal loss and maintain efficient communication networks.

- High Data Volume Handling: Custom cables in the telecommunications industry are engineered to manage large data transfers. These cables support extremely high amounts of information passing through undersea networks at very fast speeds, keeping global communication going. Advanced materials in these cables help maintain data integrity over long distances.

- Signal Integrity: Maintaining signal integrity is critical in telecommunications. Custom cable assemblies use sophisticated shielding techniques to minimize electromagnetic interference. This protection keeps signals clear and strong, allowing for uninterrupted communication across continents.

- Durability in Harsh Environments: Since these cables are undersea, they need to withstand the extreme conditions at those depths. Custom cables can resist pressure, temperature variations, and potential damage from marine activities.

Transportation Industry

In the transportation industry, custom cables connect various electronic systems in vehicles, trains, and aircraft. These cables need to be durable and reliable, ensuring the safe and efficient operation of transportation systems. Custom cable assemblies designed for the transportation sector can withstand vibrations, temperature changes, and exposure to automotive fluids. This ensures that communication, control, and power distribution systems function seamlessly.

Invest in Reliable Custom Cable Solutions

Custom cables meet the diverse needs of key industries, providing the reliability and performance required for success. By understanding specific requirements and following best practices in design and material selection, we can help you create cables that withstand the most demanding environments. At Cables Unlimited, we deliver high-quality, custom cable solutions tailored to your unique applications in the USA. Contact us today to learn how our expertise can help you achieve your goals with our custom cables.