The Solar Energy Industries Association (SEIA) reports that solar installations of 4.6 GW through the third quarter of 2022 accounted for 45% of all new electricity-generating capacity. On top of that, energy.gov reports that 13 GW of new land-based wind turbine capacity was installed in 2021. It also says that offshore wind capacity increased by 14% to 40 GW. All those installations require quite a few cables for renewable energy systems.

Note, too, that solar and wind power are just two examples of renewable energy installations throughout the USA and the world. The other elements in this mix include energy storage systems and electric vehicle charging stations. The benefits of renewable energy can be summed up with reduced greenhouse gas emissions and reduced air pollution.

The reliability of cable systems for renewable energy takes on particular importance when considering that if a solar or wind power system is shut down for whatever reason, it cannot recover the lost energy. Bear that in mind as you consider your options for cable assemblies.

This article focuses on cable assemblies used in renewable energy installations.

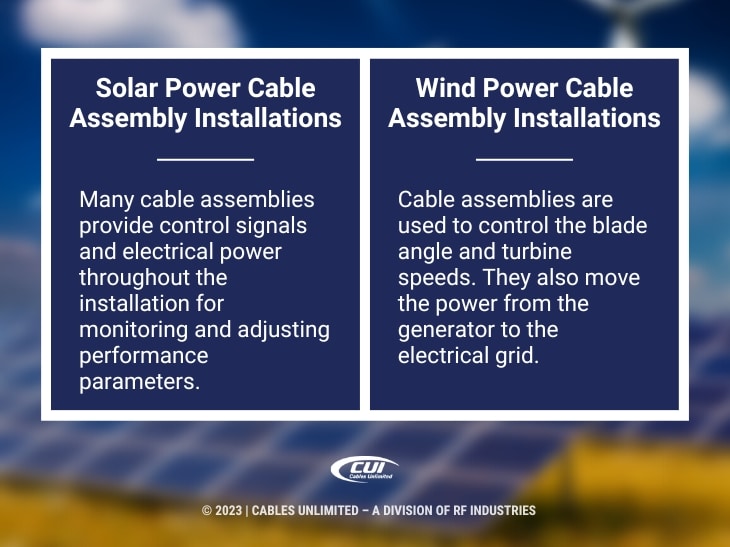

Solar Power Cable Assembly Installations

Solar panels are subject to prolonged exposure to the elements. The big one, of course, is direct sunlight. However, their outdoor installation also means considerable temperature variation, moisture that can lead to corrosion, and dust that can find its way into sensitive electronic systems.

Heavy-duty cables are used to move the electricity generated by solar panels to inverters that convert the electricity for transport to the electrical grid. But many cable assemblies provide control signals and electrical power throughout the installation for monitoring and adjusting performance parameters.

Wind Power Cable Assembly Installations

Wind turbines are based on land and offshore. They convert wind energy to electric power through their turbines. Cable assemblies are used to control the blade angle and turbine speeds. They also move the power from the generator to the electrical grid. Operation within a moving assembly subject to high wind loads, changing temperatures, and sun exposure require secure cable assembly coatings and connectors to meet safety and reliability requirements.

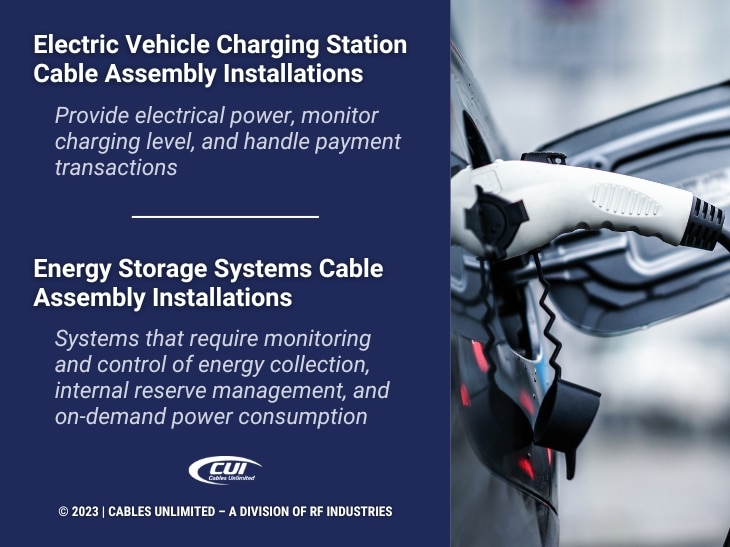

Electric Vehicle Charging Station Cable Assembly Installations

There are, of course, hundreds of cable assemblies in electric vehicles. But it doesn’t stop there. Charging station networks need to provide electrical power, monitor the charging level, and handle commercial transactions for payment. Plus, there are many home-based charging stations, all of which require the same technology to monitor charging levels.

Read more in our blog: Electric Car Wire Harnesses and Electric Vehicle Cables

Energy Storage Systems Cable Assembly Installations

Energy storage systems primarily consist of connected battery systems that require monitoring and control of energy collection, internal reserve management, and on-demand power consumption. These installations are used in several industrial, commercial and residential installations.

Benefits of Renewable Energy Cable Assemblies

The significant benefit of renewable energy cable assemblies is that they are pre-tested and ready to drop into place. This simplifies the assembly process of any system, with the alternative being to run wires and cables one at a time manually. As a result, the cable assembly saves both installation time and labor costs. It also can significantly reduce or eliminate troubleshooting time and cost when finding problems with a faulty point-to-point installation of multiple cables and wires.

Once installed, the benefits continue. The sheath and careful pre-planned routing protect the cables and wires from abrasion and exposure to hazards such as moving parts, moisture, or chemicals. In addition, the connectors, bundled cables, wires, and overall cable routing, save space. Plus, consistent routing and documentation greatly simplify the work of a technician in either troubleshooting or upgrading the system with new components.

Cable Systems for Renewable Energy Design Factors

There are many factors to consider when designing cable assemblies. They start with the overall operating environment. As noted above, with renewable energy installations, the critical factors are the operating temperature range, voltage/current levels, exposure to dust and moisture, operating flexibility requirements, and all the applicable safety and environmental regulations.

Once those factors have been determined, the specific engineering approach must be specified. That starts with the required connectors, shielding, and binding materials such as wire ties, lacing, heat shrink tubing, and insulation. On top of that comes labeling, ink stamping, tagging, and even custom colors.

Then there’s an almost staggering number of potential insulator materials that can be used to match the installation requirements. Here’s a starting list of acronyms: EPDM, PVC, SR-PVC, PE, LPDE, HDPE, TPE, TPR, PU, PP, FEP, TFE, PTFE, ETFE, PVDF, ECTFE, XLPE, and IRR/PVC. Of course, choosing the suitable materials for each application requires considerable expertise and experience, something the engineers at Cables Unlimited have built over many years in providing superior cable systems for renewable energy.

Renewable Energy Cable Assembly Manufacturing and Testing Requirements

One of the significant advantages of cable assemblies is that they can be manufactured and tested before they are installed in complex renewable energy equipment. It’s far too costly to troubleshoot after assembling the equipment, which could easily require climbing a wind turbine.

The starting point for testing and manufacturing is the IPC/WHMA-A-620 standard. It provides every cable assembly manufacturer guidance on what is acceptable and what is considered defective. This standard goes into every detail, from insulation and crimps to connector installation. Our checklist includes: labeling, continuity, wire gauge measures, crimp analysis, insulation, and even pull tests looking for broken wires and short circuits.

Here’s a quick list of the critical manufacturing requirements.

- Quality. A cable or connector failure can easily lead to failure in the field. That requires meeting specifications for high voltage, vibration, contact force, extreme temperatures, and more. Renewable energy devices, whether turbines or solar panels, must survive many adverse conditions.

- Strength and Reliability. Strength and reliability testing can range from impact survival, vibration extremes, high pressure, abrasion, and wear. That typically requires special testing designed to meet the demands of renewable energy applications.

- All-Environment Operation. From offshore turbines encountering everything from bright sunny days to hurricanes to solar panels in the desert, cable assemblies must be ready for anything.

Read more in our blog: Cables Unlimited – Cable Assembly Customization Process

We Can Help with Your Renewable Energy Cable Assembly Specification and Selection

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.