The global robotics market was valued at $65 billion in 2021, with an expected compound annual growth rate of 13%, rising to $180 billion in 2027. Within that market, industrial robots accounted for 42% of revenue, followed by military robots at 20%, healthcare at 13%, with cleaning and agricultural robots at 8% each. Whatever the industry or device, they all require robotics cable assemblies.

Those cables for the robotics industry must meet extremely high mechanical, chemical, and environmental standards. That includes rapid acceleration and deceleration, mechanical stress, repetitive bending cycles, high temperatures, and chemical exposure. Yet, as just one example, medical robots have an entirely different set of requirements.

This article focuses on cable assemblies for the robotics industry, including applications, manufacturing, and testing requirements. But first, let’s define a cable assembly.

What Is a Cable Assembly?

A cable is two or more conductors within a single jacket. A cable assembly is a group of wires or cables encased in a single tube of heavy-duty material ranging from thermoplastic rubber to vinyl to polyurethane. A cable assembly is designed for specific environmental factors, including heat, friction, moisture, and similar hazards.

Cable assemblies offer the benefits of pre-testing and drop-in use in product manufacturing. The alternative is routing single wires and cables throughout a product, hoping you’ve gotten everything installed correctly and that any environmental challenges don’t compromise the wire and cable performance.

Robotics Cable Assembly Applications

Cable assemblies for robotics follow the same pattern but with the addition of many more physical challenges due to the moving parts of the robotic unit. Plus, there are a considerable number of robotics cable assembly applications, each with its own set of rigorous requirements. Here’s a quick list.

- Industrial Robotics. This includes welding and painting robots and those involved in assembly and testing applications. Cable assemblies must withstand bending and rotation movements and varying environmental conditions. Plus, reliability is essential to keep the factory running at all times.

- Military Robotics. This includes robotics used in aerospace applications, from airborne refueling to space-based robots and even unmanned aerial vehicles and military applications. Not only are there a large number of applications, but on top of that are rigorous Mil-Spec standards that must be met. These standards for cable assemblies mean absolute reliability, standing up to harsh environments, extensive soldering and workmanship standards, and rigorous testing and inspection.

- Medical Robotics. Robot-assisted surgery allows doctors to perform surgical procedures with minimal impact on the patient. This is because tiny robotic arms and sensors, all supported by cable assemblies, require very small openings compared to traditional surgery. Robot-assisted surgery can also allow remote operations worldwide by a medical specialist in, for example, Boston, bringing medical expertise to where it’s needed.

- Exoskeletons. Wearable and exoskeleton advances continue at a rapid pace. They can not only support those with muscular limitations but increase the strength and endurance of those working in extreme conditions. Fail-safe is a must for any cable assemblies as well as standing up to harsh conditions over long periods of time.

- Logistics Robotics. Installing robotics systems in warehouses has dramatically reduced errors and shortened delivery times. Plus, it eases the burden on warehouse staff. A key component is mobile automated guided vehicles, chock full of cable assemblies, that transport materials for storage and delivery and do so around the clock. It’s all about improving supply chain processes from start to end.

Critical Requirements for Robotics Cable Assembly Manufacturing

There are three critical requirements for cable assemblies for the robotics industry. Here’s a summary of each one.

- Robotic Cable Assembly Protection. Cable assemblies must be flexible enough to move with robotic motion, which can be very flexible and fast. Yet they must be strong enough to protect the cables within the assembly molding. That requires a perfectly developed balance between flexibility and protection.

- Dynamic Cable Assembly Movement. Cable assemblies not only need to move with the robotic motion but also consider that robotic motion is now up to six-axis. That means planning must be rigorous to determine how the cable assembly will be moving and how to provide the right cables within the exterior molding that can withstand the motion. This must also consider the lifetime of the installation and the required durability.

- Cable Management for Robotics. Robotics installations must consider protection and movement as outlined above and review the full installation for proper cable management. Possible solutions are multiple cable assemblies that terminate in the required connectors at a low motion point within the robot. For example, it’s often recommended that robotic cable assemblies be segmented into three separate assemblies. One to address the robot’s sixth to third axis, another for the third to second axis, and a final assembly for the second to the first axis. This can optimize the installation by minimizing tangling and interference with the robot’s motion.

Of course, all these considerations come together within the context of the complete robotics installation. That means costs must also be considered to optimize the full cabling design. That requires working with a reliable and experienced custom cable assembly manufacturer.

Read more in our blog: Cables Unlimited – Cable Assembly Customization Process

Robotics Cable Assembly Testing Requirements

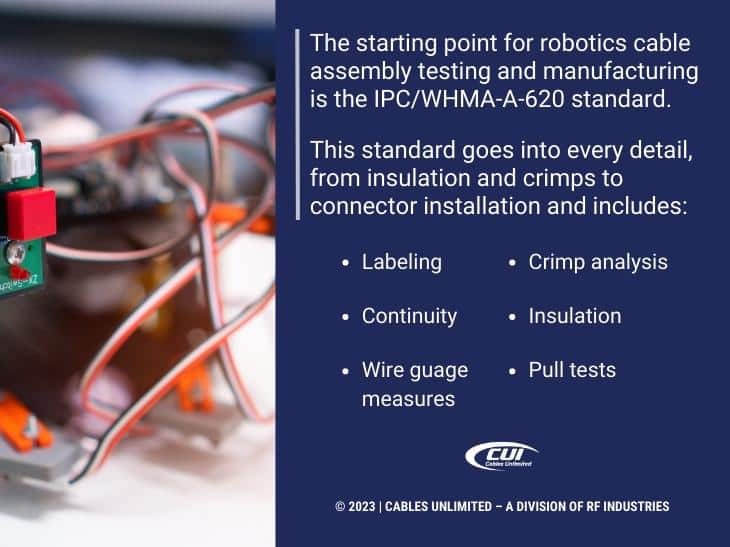

One of the significant advantages of cable assemblies is that they can be manufactured and tested before they are installed in complex robotic equipment. It’s far too costly to troubleshoot after assembling the equipment.

The starting point for testing and manufacturing is the IPC/WHMA-A-620 standard. It provides every cable assembly manufacturer guidance on what is acceptable and what is considered defective. This standard goes into every detail, from insulation and crimps to connector installation. Our checklist includes: labeling, continuity, wire gauge measures, crimp analysis, insulation, and even pull tests looking for broken wires and short circuits.

Here’s a quick list of the critical cable assembly manufacturing requirements.

- Quality. A cable or connector failure can easily lead to failure in the field. That requires meeting high voltage, vibration, contact force, extreme temperatures, and more specifications. Robotics cable assemblies must survive many adverse conditions, from high-speed starts and stops to repetitive motion and twisting. Simulating these movements, followed by rigorous testing, is a must to ensure quality.

- Strength and Reliability. Strength and reliability testing can range from impact survival, vibration extremes, high pressure, abrasion, and wear. That typically requires special testing designed to meet the demands of robotic applications. Critical tests include pull testing, continuity testing, and looking for broken wires or shorts.

- All-Environment Operation. Robotics cable assemblies are installed across various applications from industry to medical to aerospace and more. That means testing must be designed to simulate these environments to ensure that any potential failure points are found and corrected before robotics cable assembly manufacturing.

Find out more in our blog: Critical Manufacturing Options for High-Temperature Cables

We Can Help With Your Robotics Cable Assembly Specification and Selection

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables Unlimited offers much more than state-of-the-art manufacturing—our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.