The wiring harness market is estimated to reach $191 billion by the end of 2030. The list of applications covers a broad range of industrial, robotics, and commercial products. Here’s the list: automotive, marine, aerospace, defense, gaming, medical equipment, commercial refrigeration, food machines, consumer technology, fitness equipment, power, energy, agricultural equipment, industrial, mechanical lifts, elevators, escalators, batteries, and many others.

Our recent article, The Ins and Outs of Custom Wire Harnesses, briefly explored the reasons behind this growth. This article addresses the use cases of wire harnesses, including the benefits, manufacturing, and testing.

What Is a Wire Harness?

A wire harness is an assembly of multiple cables and wires bundled within an insulating material. It uses tie wraps, loom tubing, and other sleeving components to bundle the wires and cables. The cables and wires range from fiber optics to coax to copper.

Note that a wiring harness is different from a cable assembly, which is two or more conductors encased within a single tube of heavy-duty material. If you’re interested in cable assemblies, see our article Wire Harnesses and Cable Assemblies — What’s the Difference? for more information.

Wire Harness Benefits

One of the significant benefits of wire harnesses is that they can be manufactured and tested before installation. It’s far too costly to engage in troubleshooting after the equipment is assembled.

Since the wire harness is bound together, it also provides a safe routing pattern. It further simplifies the wiring interconnections by delivering an all-in-one integrated drop-in installation across multiple connection points. The alternative is routing every wire and cable through a product and hoping you’ve installed each one correctly. A wire harness saves time and trouble.

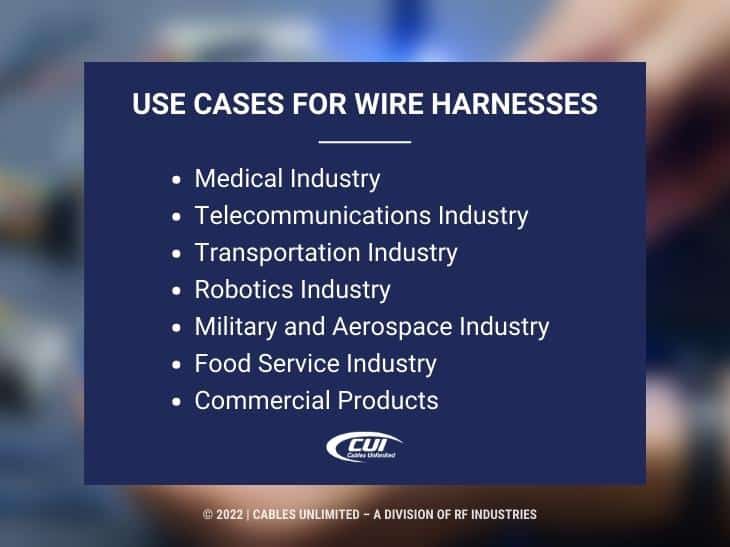

Use Cases for Wire Harnesses

The list of use cases for wire harnesses covers nearly every type of imaginable product, as noted earlier in this article. Here are a few highlights to consider.

Medical Industry

Medical devices have extremely rigorous requirements. This includes wire harnesses that are durable, biocompatible, and highly reliable. Two examples are defibrillators that are stored for months but need to function immediately without failure. Similarly, dialysis machines need to run flawlessly 24/7/365. The list continues, and the wiring harness complexities multiply with the device’s requirements.

Telecommunications Industry

We’ve written about the growing demand in the telecommunications industry as the 5G global infrastructure expands, followed closely by 6G wireless networks and further developments, including small cell networks. That requires custom copper and fiber optic assemblies across the small cell networks placed on lampposts and nearly everything else to ensure seamless coverage throughout a city, as one example.

Transportation Industry

The transportation industry is rapidly automating almost every function, from autonomous vehicles to traffic management. Cabling is needed to support traffic signal control, traffic monitoring, license plate recognition, toll systems management, and parking management. All that requires custom wire harnesses throughout the network. For further insight, see our article Fiber Optics Driving the Transportation Industry.

Robotics Industry

Wire harnesses are used throughout robotic assemblies and products. They range from power distribution to data transmission to servo motor cables. They are often called upon to be high or continuous flex plus resistant to impact and even flames. Their motions are often repeated millions of times and subjected to high acceleration, torsion, and bending. And, of course, they need to be durable and trouble-free.

Military and Aerospace Industry

Mil-Spec cabling and wire harnesses must meet stringent requirements backed by rigorous quality control. The applications include aircraft, drones, spacecraft, weapons systems, ships, submarines, radar, and power plants. They are all expected to operate in harsh environments with high vibration, abrasion, and temperature extremes.

Manufacturing Custom Military Cables for Unique Applications

Food Service Industry

The food service industry requires cabling for ovens, warmers, slicers, mixers, and more. These harnesses have some very stringent requirements since they are used in food preparation. There is also a myriad of different products and applications. Those generally require custom cables and wire harnesses.

Commercial Products

Wire harnesses are also used in kitchen and laundry appliances where microprocessors are becoming increasingly into play and need to connect to motors, relays, and sensors. Then there is everything from coffee makers to computers and video displays. The list is long and quite varied. Just a quick look through your home or office will reveal that almost every product has a least one, if not more, wire harnesses.

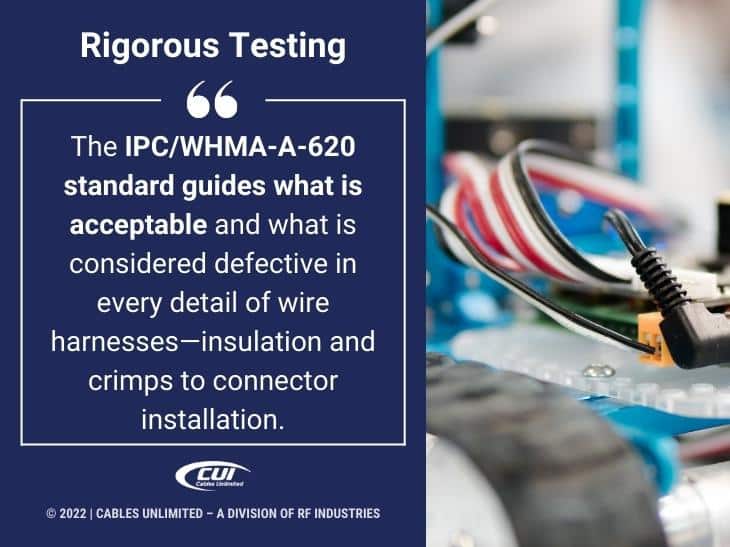

Manufacturing and Testing Wire Harnesses

From the list of use cases above, you can tell that manufacturing needs to be flawless. The testing also needs to be rigorous to ensure the harnesses work the first time and every time. After all, that’s one of the advantages of wire harnesses, they can be tested and their operation verified before they’re installed.

The IPC/WHMA-A-620 standard guides what is acceptable and what is considered defective in wire harnesses. This standard goes into every detail, from insulation and crimps to connector installation.

For example, our wire harness checklist includes the following:

- Accurate labeling and checking for defective wires and insulation.

- Continuity.

- Correct wire gauge and crimps.

- Wiring is free of moisture and corrosion.

- Pull test on wires and cables.

- Testing for broken wires and shorts.

We Can Help

Our name is Cables Unlimited for a reason. Whatever wire harness you need, we can provide it.

If your requirements are already specified and ready for a quote in your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing. Our dedicated team is also known for going to great lengths to meet the needs of our customers. That includes working around the clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. You can also email us or complete our contact form, and we’ll get back to you.